Technical Note

CONDENSATE AND SPENT LEESE POLISHING UNIT FOR CONDENSATE FROM EVAPORATION OF BIODIGESTED SPENTWASH AND RAW SPENTWASH FOR DISTILLERY

NECESSITY OF CONDENSATE & SPENT LEESE POLISHING

- With the water source getting scares and distillery consuming considerable water, both for fermentation addition and cooling tower make up, the efforts are initiated to identify partially polluted water streams and reuse the same after selective treatment.

- The zero discharge technological options have volume reduction component in the form of ‘MEE’ as common. This results in voluminous condensate, which has contamination concentration due to volatile organic matter and which cannot be reused as it is. Added to this is largely neglected stream of ‘Spent Leese’, which was not dealt with in a scientific way.

- With the controlling agencies becoming more stringent in their approach for ‘Zero Discharge’, these two streams cannot be neglected and the treatment structure has to be part of a comprehensive plan of achieving zero discharge along with principal treatment and disposal aspect of Spentwash.

DEVELOPMENT OF TECHNOLOGY OF DISTILLERY CPU

It is worthwhile to note that even before this impetus on zero discharge came into being, this aspect was considered and effective measures were taken not only for treatment and disposal but for effective reuse of the same in two major industrial houses in India, 5 years back.

GENERATION OF CONDESATE

Condensate is generated from concentration of Biodigested Spentwash in MEE.

CONDENSATE POLISHING UNIT FOR CONDENSATE AND SPENT LEESE FROM BIODIGESTED SPENTWASH EVAPORATION

A need was felt to develop technology for this condensate also, as majority of distilleries, have already followed this route of spent wash treatment, working for years.

The shortfall in mass balance for the composting process to be scientifically followed has made it mandatory to adopt a MEE after bio-digester, to reduce and bring the volume of spent wash within treatable limits for composting process.

- Although this condensate quality is far better than that of from the evaporation of raw spent wash, it is still required to be treated before reuse.

- The 1st plant in India in this regard was also designed and developed 10 years back and the results for this were satisfactory and working with same efficiency since then.

- The condensate from evaporation of bio-digested spent wash along with spent leese is working at 3 distilleries in India, 1 distillery in Philippines and scheduled to be provided for a project in Sudan.

TREATMENT APPROACH

There are two thoughts of treatment prevalent

- Physico-Chemical Mode: In this, mainly steam stripping of Condensate is used. Besides the disadvantage of conversion of dissolved pollution to aerial one, there are limitations to the efficiency, for the reasons given hereunder

- Biological removal of Ammonical component: Besides conversion of Ammonical Compounds in inert gases, this method, well established in its kinetics now, offers advantages like no use of resources like steam which are scarce and costly.

The following are broad comparative aspects of the two major methods

- There are limitations to Physico-Chemical Method Efficiency, and as a result, we are vested with Water to be used with Considerable Ammonical concentrations.

- However, the major aspect of concern that these stripping does not remove the Volatile Organic Matter concentrations and therefore impart considerable COD and more importantly BOD,WHICH IS NOT ACCEPTABLE IN ANY RECEIVING BODY. As against this, all these parameters are tackled to respective limits in a biological treatment.

- Once stabilized, the resource consumption and thereby working costs are the minimum for biological treatment and therefore it is economical proposition as well on a long run.

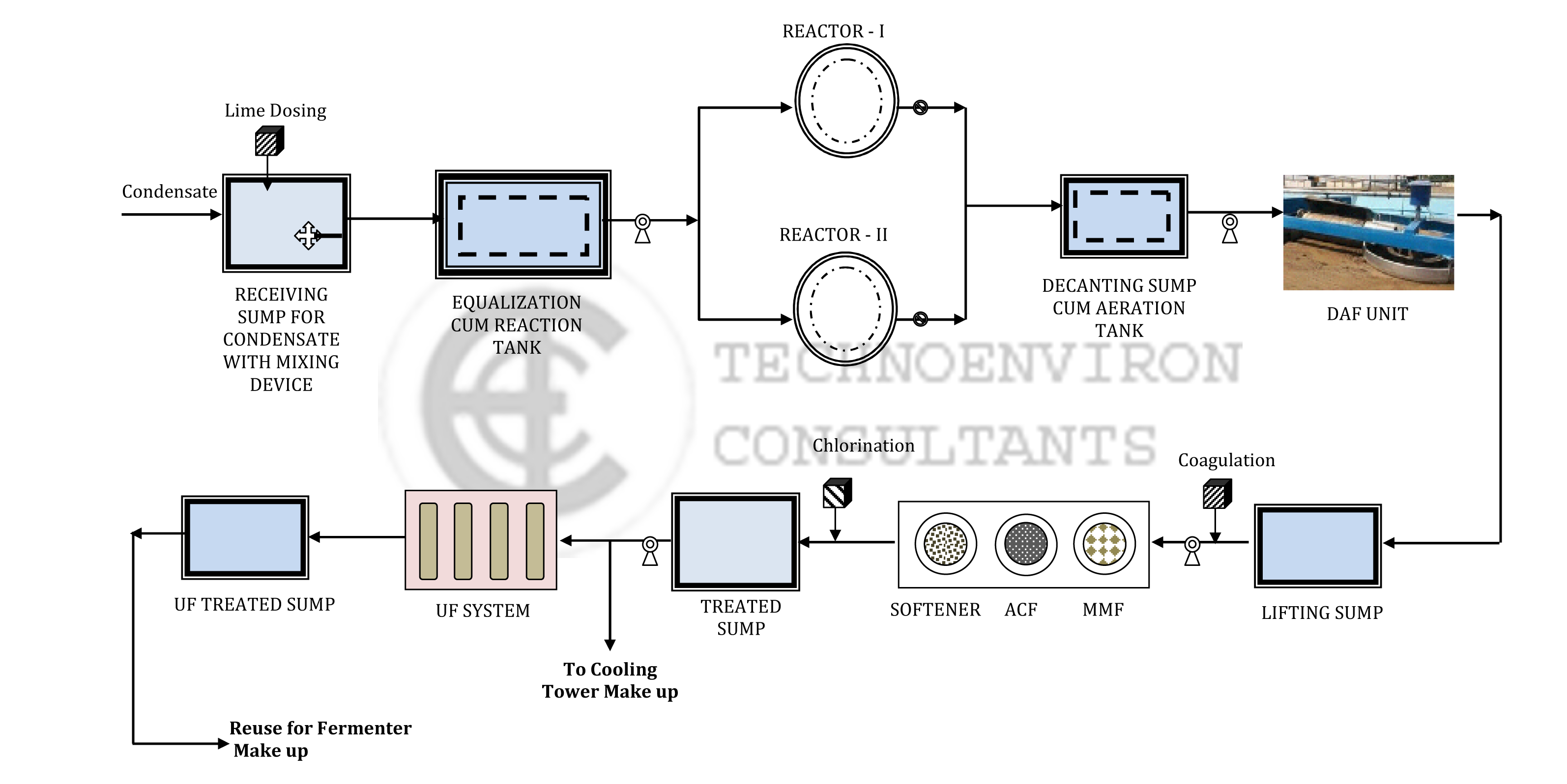

The treatment scheme for condensate polishing unit involves the utilization of biological mode, specially developed to treat not only trace organics, but basically the Ammonical nitrogen.

The treatment scheme therefore comprises of a Nitrification – De-nitrification. The design approach and kinetics developed after years of monitoring data base has helped in optimization of chemicals and energy requirement of the process, with judicious working of both the modes.

RECONNAISANCE

With the growing awareness of achieving zero discharge, that too with 100% recycle of the partially polluted wastewater streams. Condensate polishing units have come into existence in the distillery industry, for treating condensates evolved in the main treatment scheme for Spentwash Treatment. Development of Biological Treatment and successful performance of the same for over 4 years is a milestone in the development of the technology evolved after years of continuous monitoring and upgradation in this industry.

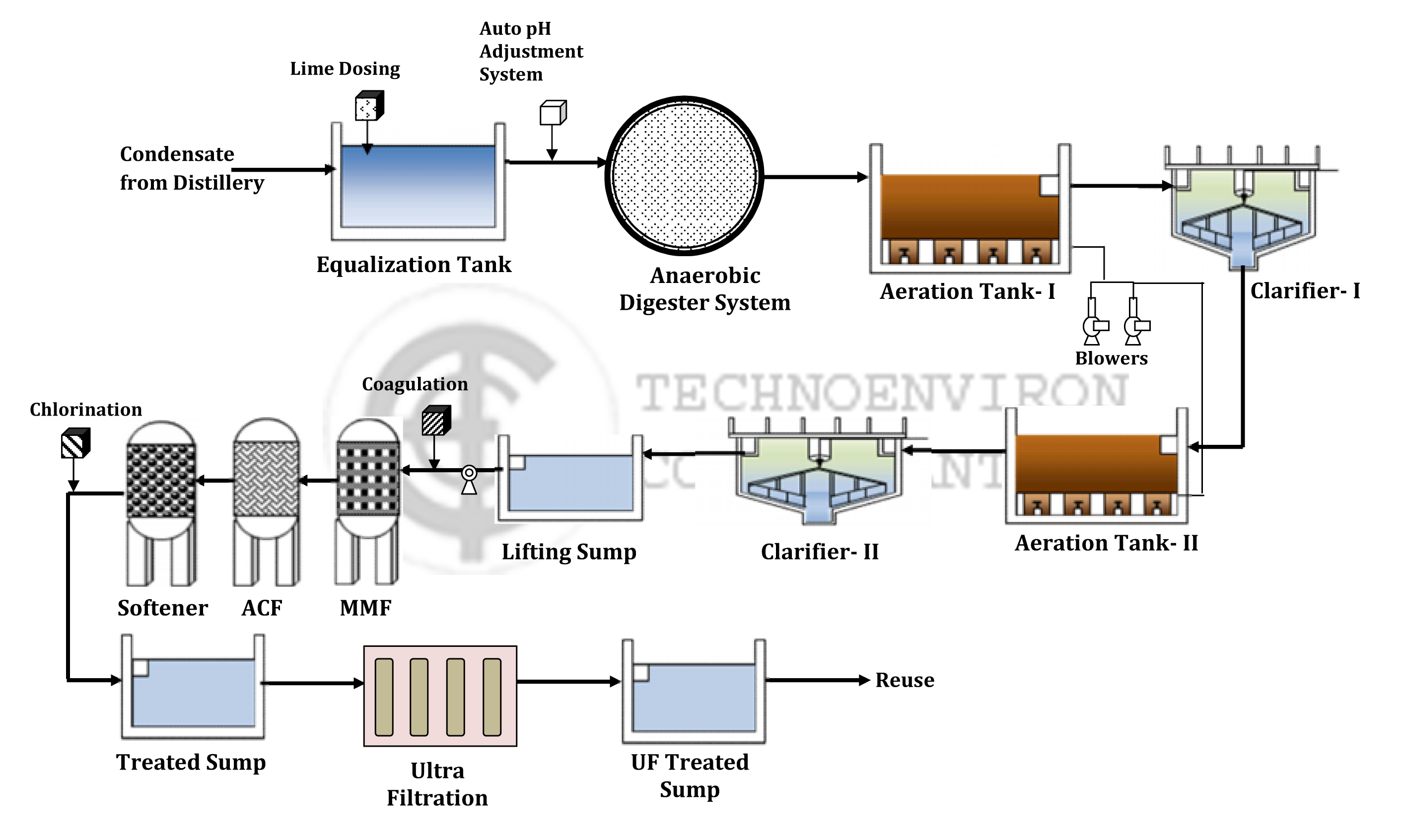

SCHEMATIC PROCESS FLOW DIAGRAM FOR CONDENSATE POLISHING UNIT FOR DISTILLERY

CONDENSATE AND SPENT LEESE POLISHING UNIT FOR CONDENSATE FROM EVAPORATION OF RAW SPENTWASH FOR DISTILLERY

DEVELOPMENT OF TECHNOLOGY OF DISTILLERY CPU

It is worthwhile to note that even before this impetus on zero discharge came into being, this aspect was considered and effective measures were taken not only for treatment and disposal but for effective reuse of the same in two major industrial houses in India, 10 years back.

GENERATION OF CONDESATE

Condensate is generated from concentration of Raw Spentwash in MEE.

CONDENSATE POLISHING UNIT FOR CONDENSATE FROM RAW SPENTWASH EVAPORATION

- A systematic approach by evolving biological treatment by proper reaction Kinetics was carried out, almost 10 years back for condensate from evaporation of Raw Spent wash and the results for this 1st plant in India were satisfactory and working with same efficiency since then.

- It is interesting to note that the treated condensate and spent lease is not only being used for cooling tower makeup- but also for Fermenter addition.

- Modifications and Up gradation in the working process were carried out during these years to ensure higher treatment efficiency and almost negligible use and cost of neutralizing chemical

- The Condensate Polishing along with spent lease treatment for Raw Spent wash is working at 5 places in India and one in Ethiopia for last 12 years.

TREATMENT APPROACH

Properly designed anaerobic digestion approach with complete mix technology and two stage extended aeration system helps to achieve reduction of organic matter. Tertiary treatment approach is suggested as a polishing treatment comprising of chlorination, coagulation, multimedia filtration, activated carbon filtration and followed by softener and Ultra filtration to attain quality of condensate suitable for reuse. A scheme with tested biological reaction parameters and kinetics shall be designed to suit the constraint conditions.

RECONNAISANCE

With the growing awareness of achieving zero discharge, that too with 100% recycle of the partially polluted wastewater streams. Condensate polishing units have come into existence in the distillery industry, for treating condensates evolved in the main treatment scheme for Spent wash Treatment. Development of Biological Treatment and successful performance of the same for over 10 years is a milestone in the development of the technology evolved after years of continuous monitoring and up gradation in this industry.

SCHEMATIC PROCESS FLOW DIAGRAM FOR CONDENSATE POLISHING UNIT FOR DISTILLERY