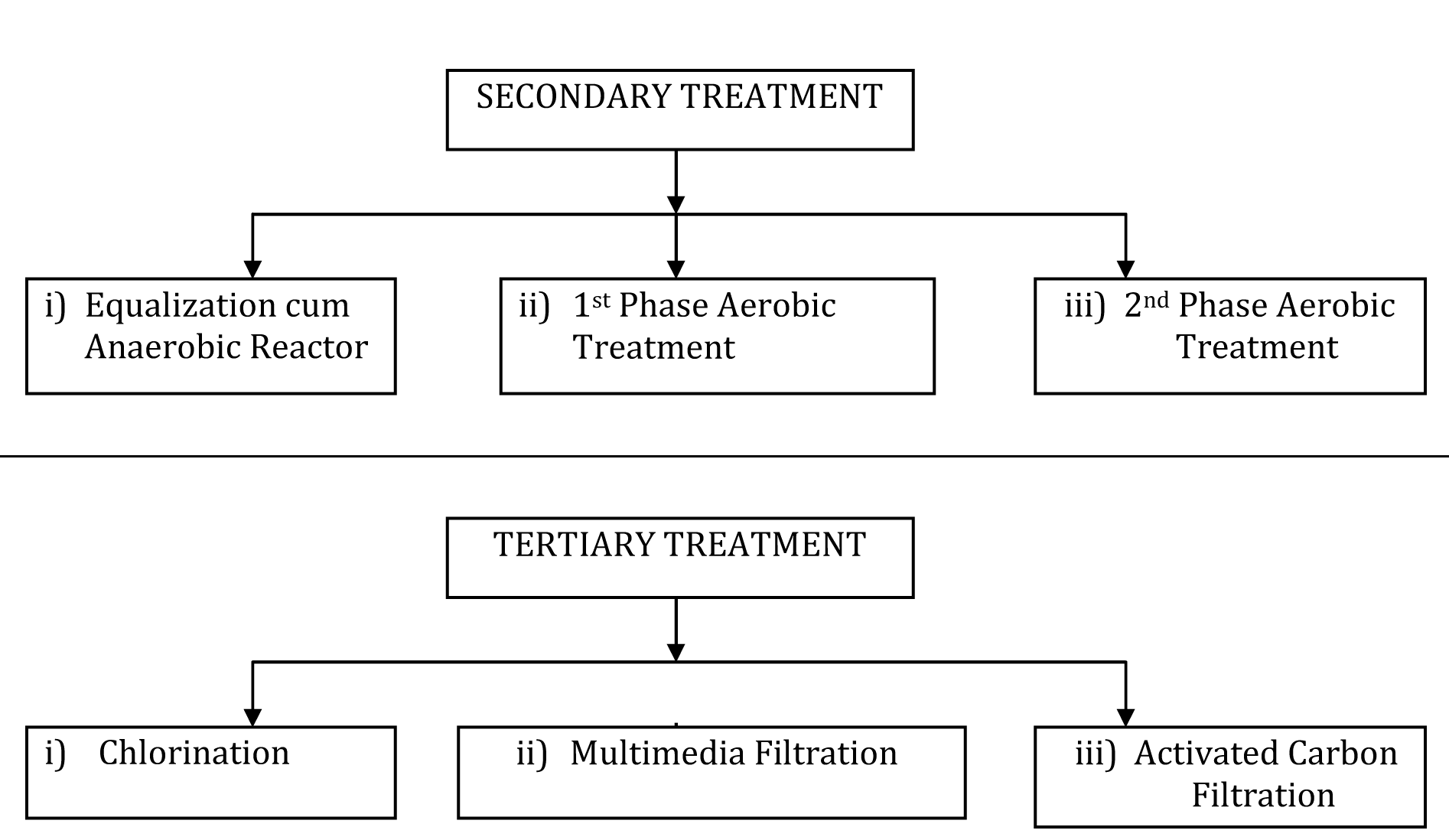

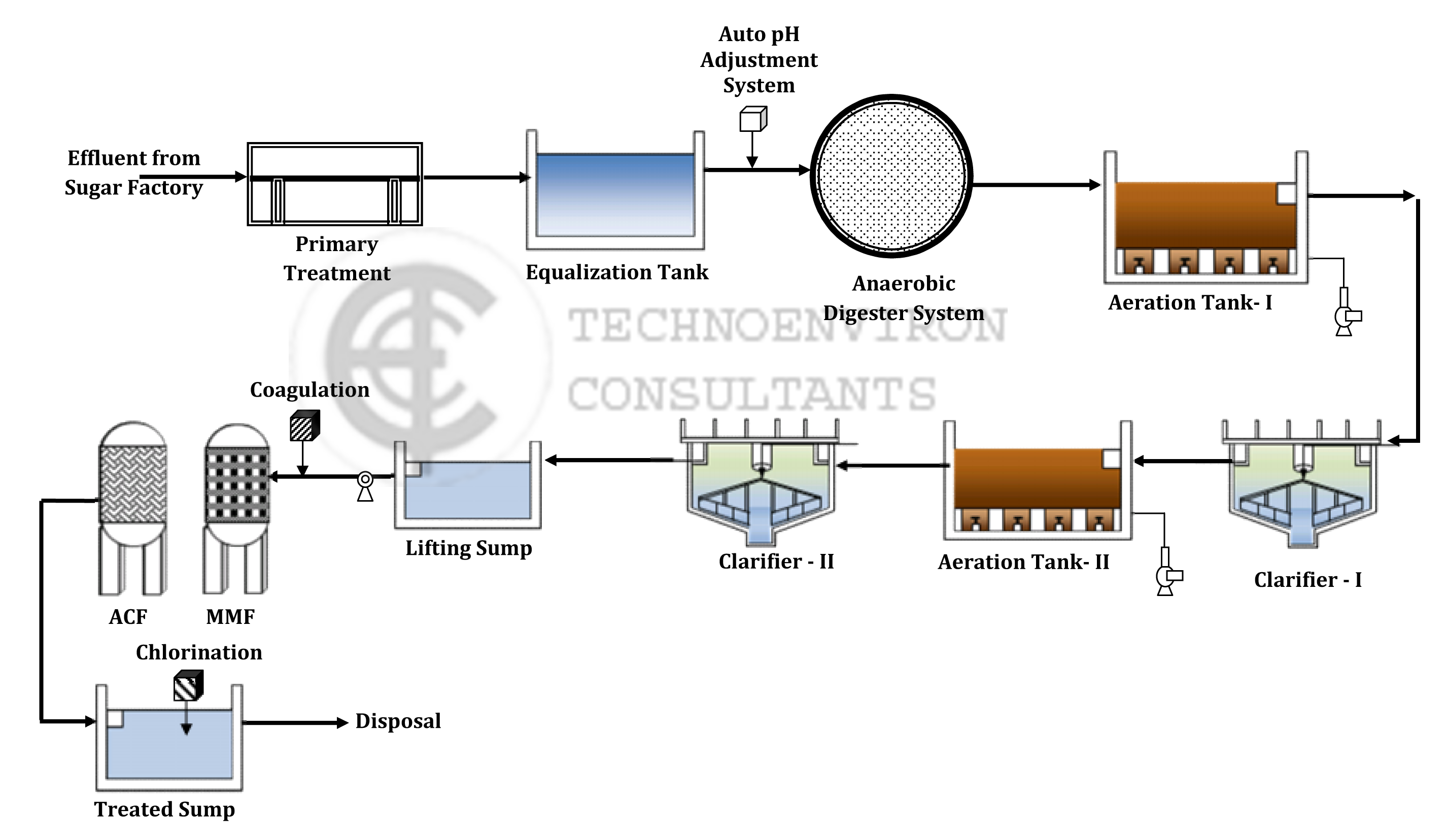

Observing the characteristics, it is evident that the combined effluent is biodegradable. It is also observed that a Primary anaerobic Phase Biological Treatment imparts two advantages, one, since the phase does not involve mechanical aeration, it reduces organic matter concentration by more than 50% efficiency, without energy input, thereby making the total Energy requirement by more than 50% of Conventional treatment. But, the most important advantage observed in case of Sugar factory effluent is the capacity to absorb shock loading is far better, as compared with that for Aerobic mode. The effluent shall therefore be subjected to Anaerobic phase.

The most effective Aerobic Treatment mode determined for the sugar factory effluent is ‘Extended Aeration’ where the F/M is kept low and MLSS concentration high by optimum sludge recirculation, Two-stage Aeration-Clarification Process is suggested followed by Tertiary Treatment.

Tertiary Treatment

The treated effluent after this treatment shall achieve the stipulated norms for disposal on land for irrigation. In order to further safeguard against minor variations, a tertiary treatment comprising of Multimedia Filter for reducing turbidity and Activated Carbon Filter for reducing trace colour and organic matter is proposed. This will render the treated effluent fit for reuse for non-process applications.

Excess Sludge Drying

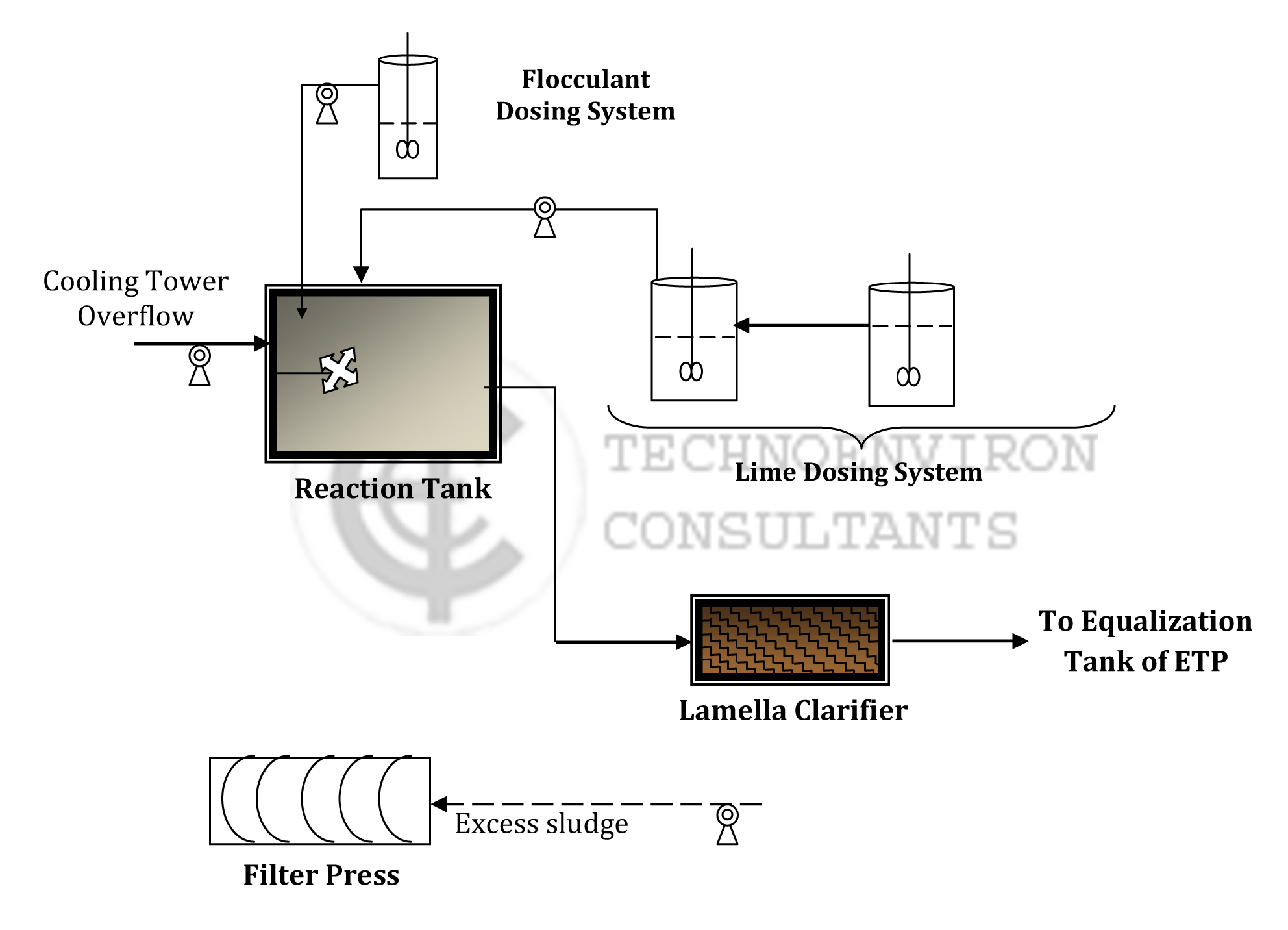

For Drying of the excess sludge, in place of the present Sludge Drying Beds, which results in odour nuisance and which is a Manpower intensive process, Filter Press is recommended, which shall result in Drip-free sludge.